Rosenqvists RoastR traditionally cooks snack pellets and are expanded using frying oil or hot air as heat transfer media. With RoastR, heat is applied through salt - the next step in snack innovation.

The reason for using salt as heating media is its superior thermal conductivity capability. Hence RoastR provides the opportunity to produce fat-free snacks at low cooking temperatures.

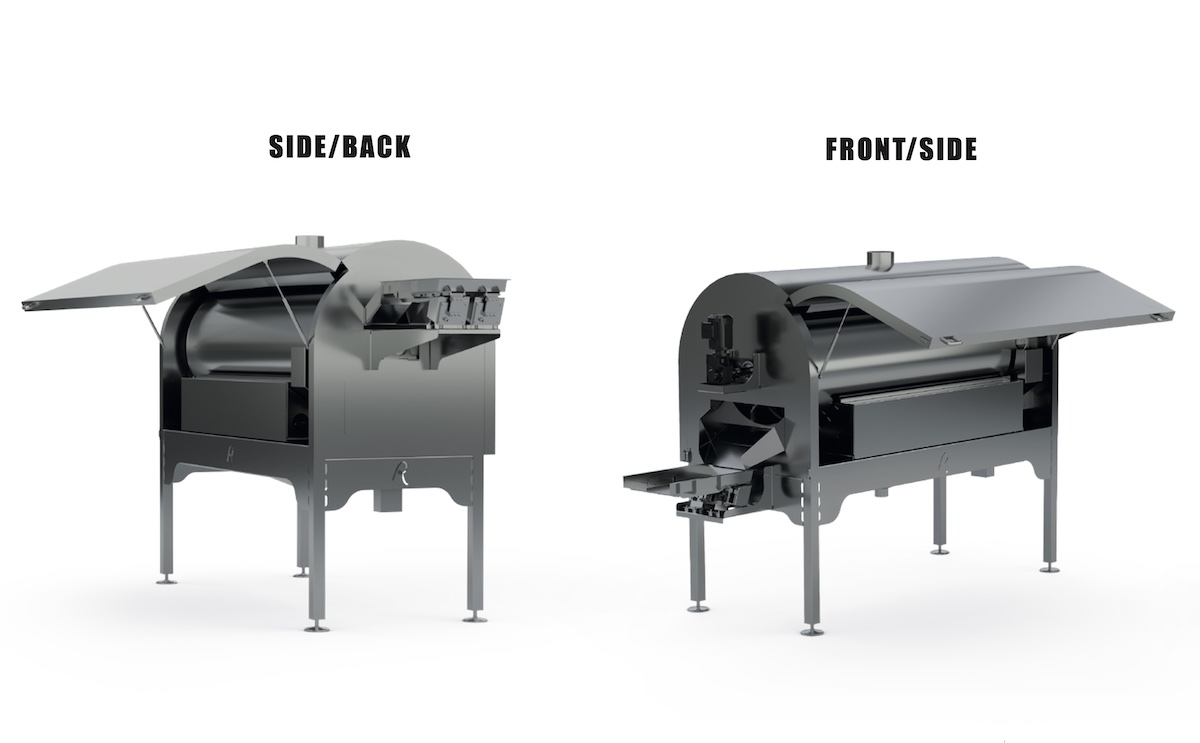

Through the patented design, salt is transferred in a mechanical loop through a 2-way process screw. Cooking and expanding the pellets in heated salt one way, filtering out product, and re-heating salt the other way. Since a specific shape and size of granulated salt is used, heat is gently applied and steam from pellets is easily transferred out with the exhaust.

Creating a perfect environment to reduce the water content of the product and making sure that the product is not sticking to the surface of the process screw. Expected salt uptake in product from process is 0,1-0,4 %, which is related to raw pellet formula and surface smoothness and starch gelatinization level after roasting. Heating is applied through infrared heating elements placed beneath the process screw.

The new and unique features with their RoastR are:

- Gentle cooking and expansion of pellets

- 0% fat used

- Pellets:

- All available 2D pellets

- High protein

- High fresh vegetable content

- Variable speed of process screw, controlling roasting time

- Electrically heated – Quick installation and commission

- Easy to operate and maintain

- Low running costs

- No cost for waste oil handling

RoastR Advantages:

- Steam channel exhaust

- Infeed shaker

- Thermal unit

Rosenqvists RoastR